Chimneys

Home » Chimneys

Chimneys & chimney accessories

Among the general contracts that MTM has, is the installation and maintenance service for commercial and industrial heating and ventilation systems, and climate control throughout the Northwest of the USA. We are committed to the operation from start to finish and attention to detail.

Some systems are located close enough to the roof or the wall they penetrate that they do not require chimneys to prevent condensation of the flue gases from occurring.

Moreover, MTM Sheet Metal offers installation and maintenance service for commercial and industrial heating and ventilation systems, and climate control throughout the Northwest of the USA. We are committed to the operation from start to finish and attention to detail.

Types of chimneys and their different styles will vary across geographic areas of the world, and even look dramatically different across the nation depending on the type of house or roof, but the fundamentals of how the systems operate are the same. Chimneys are typically built with chimney liners inside of them for added insulation from cold ambient air temperatures and winds that could otherwise cool the flue pipe and allow the gases to condense.

Chimney liners also assist with airflow and ventilation of the rising gases. Flue pipes end where they connect to the chimney liner, which are usually constructed of varying forms of metal or clay and run the entire length of the brick-and-mortar chimney. Chimney liners terminate with a cap on top to prevent water from entering. When settling claims with these items, adjusters should make sure to get thorough evaluations for an accurate cause of loss and scope of damage.

Efficiency

Variety

MTM SERVICES

Our way of working is very flexible and focused on the customer. We are organized in customer teams where the distance from management to work-force is very short, and we carry all responsibility towards the customer. This means that we can take on assignments with short lead time and high demands on flexibility and delivery assurance.

-

Personalized attention

Personalized attention

-

Product diversity, from small to large series.

Product diversity, from small to large series.

-

Products in projects, small and large projects.

Products in projects, small and large projects.

-

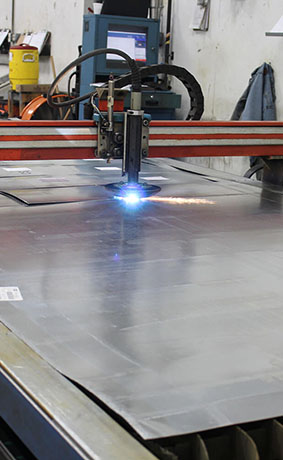

Design in modern CAD environment.

Design in modern CAD environment.

-

Overall udertaking, from design to installation.

Overall udertaking, from design to installation.

-

Projects to reduce costs of products and systems.

Projects to reduce costs of products and systems.